Case Study

Partnering With Visionix

Visionix is a 20-year-old French organization in ophthalmic diagnostics, presented with a need to develop a comprehensive ophthalmic screening device for screening the anterior and posterior of the eye.

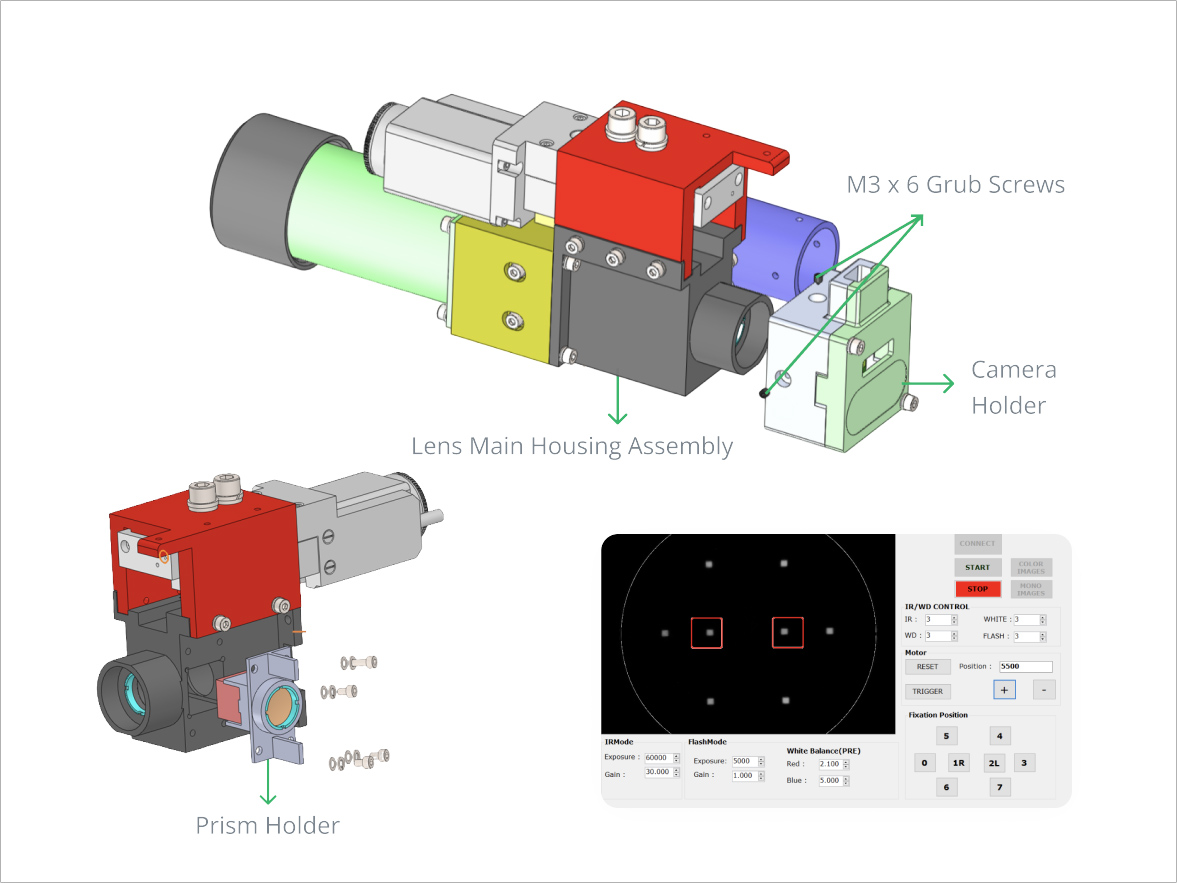

Tridios in-house R&D team developed an “automated easily retrofitted imaging module” currently integrated with VX-650+, a multi-modal device that conducts 24 eye exams in 90 seconds along with Retina!

Clinical and regulatory testing was performed as per EMC/EMI/ IEC and other regulatory compliances

Product stands currently approved and has the FDA 510(K) and CE mark

Continuous manufacturing and supply underway for these modules for VX-650+

Third-Party OEM Manufacturing

Key Features

Integrated completely automatic system

Integrated camera/Autofocus and Auto-capture feedback mechanism

Regulatory approval (EMC, EMI, Safety….)

Biocompatible medical grade plastics and rubber material utilization

Inbuilt LCD Display system Party OEM Manufacturing

Processes Utilized

CNC machining and anodizing

UL/ROHS Compliant and traceable EMS for PCB boards

Biocompatible Plastic and rubber parts through Mould and 3D printing.

ISO Class 8 Assembly line and QA/QC as per 13485

Partnering For Respiraid

Key Features

Automated Respiration Assist device

Motors precision control system, Volume output

Regulatory approval (EMC, EMI, Safety, ISO-80601-2-84/ 80601-2-12 Safety Standard compliance….)

Biocompatible medical grade plastics and rubber material utilization

Inbuilt LCD Display system

Processes Utilized

CNC machining and Sheet metal parts

UL/ROHS Compliant and traceable EMS for complex PCB boards

Traceable control and volume measurement systems

Biocompatible Plastic and rubber parts through Mould and 3D printing.

ISO Class 8 Assembly line and QA/QC as per 13485